DynamIx VUDiagnostic imaging software is an all-in-one software suite that integrates storage management, image analysis tools and file-sharing capabilities into a single platform.

The platform provides a wide range of features, including ergonomic usage, flexible architecture and data security to maximize your diagnostic imaging software options. Diagnostic imaging software enables you to optimize your imaging systems throughout the process, from film digitization to direct and computed radiography. With this comprehensive system, a wide range of industries can manage testing, inspection and assessment requirements. As an all-in-one software suite, our modular platform fully complies with industry standards for transmission, image storage, retrieval and other critical processes. |

Overview

Key Features of DynamIX VU

With diagnostic imaging software from Fujifilm, you have access to a wide range of capabilities for diverse applications. The DynamIx VU offers several key features for streamlining your operational requirements:

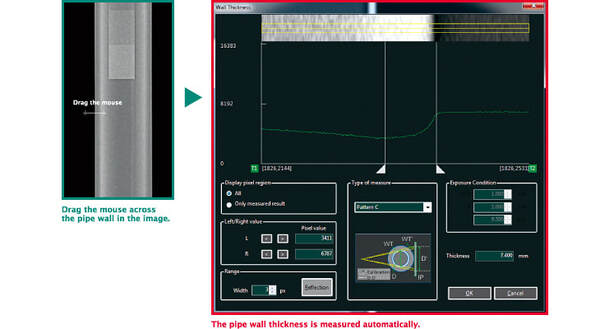

- An Automatic thickness measurement tool to simplify corrosion tests with precise Fujifilm technology. The pipe wall thickness is automatically measured based on Fujifilm's precise image analysis technology to make an inspection more efficient and stable.

- Computerized contrast/density normalization, meeting the ASTM standard.

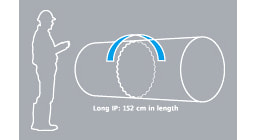

- Ability to read IPs up to 152 cm long to efficiently inspect objects of various sizes.

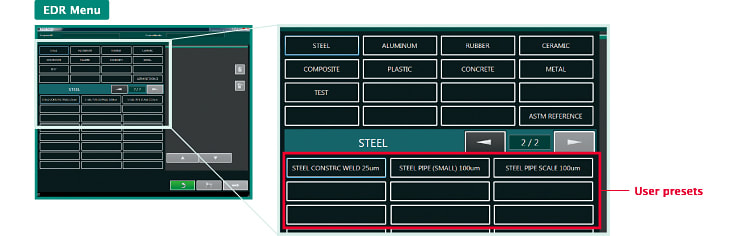

- Density parameter preset feature for optimized image adjustment.

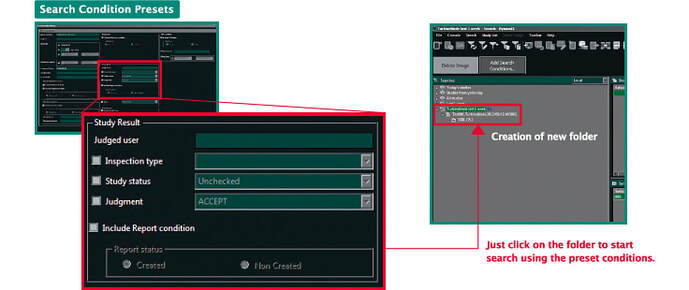

- Rapid data search with preset conditions.

- Intuitive interface to smoothly transition from image reading to inspection windows.

Advantages of DynamIx Vu

- The world's top class* high spatial and density resolution and excellent signal to noise ratio (SNR) produce superb image quality.

- Fusion of Fujifilm's advanced technologies used in image reader, software and IP realizes images of the finest quality possible expected in digital imaging.

- Unique image processing and wide dynamic range bring high accuracy to every inspection.

Operational Efficiency

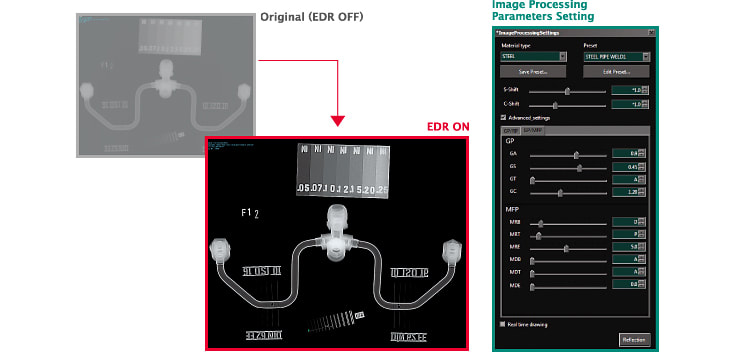

Density parameter presets are available for more efficient image adjustment.

The user can customize and preset the automatic density adjustment parameter (Exposure Data Recognizer: EDR) suitable for the test object. Easy density adjustment is possible with just one click.

The user can customize and preset the automatic density adjustment parameter (Exposure Data Recognizer: EDR) suitable for the test object. Easy density adjustment is possible with just one click.

Optimized Flexibility

With a flexible network configuration, the DynamIx VU allows for a streamlined workflow fitting your unique operations. Includes centralized management of inspection data at multiple sites via intranet or Major ERP Applications.

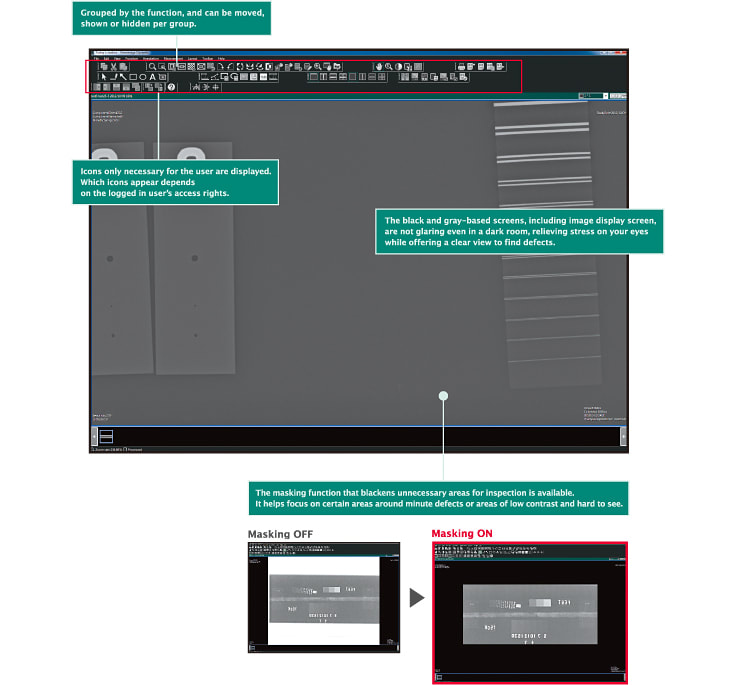

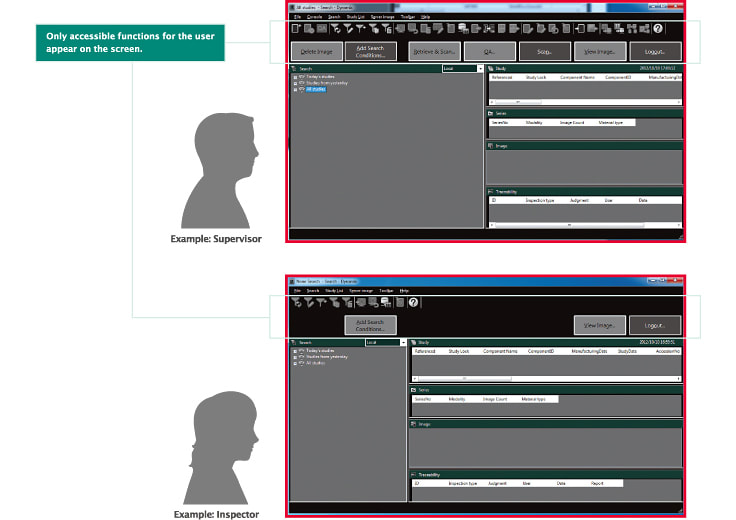

Strengthened security with user authority control

The system allows user access rights and control of individual functions to manage unauthorized tools and keep the workspace secure.

Intuitive design

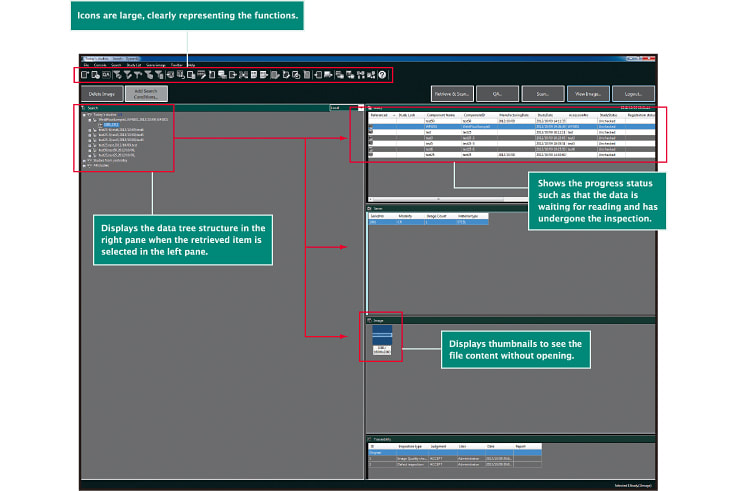

The user-friendly interface makes viewing work status management and conducting data searches simple. All the information is accessible on one screen.

Greater Assessment Precision

The system automates image assessment, eliminating human error for increased accuracy.

Features

Quality Image

Promising keys for outstanding image quality ― world's top class* high spatial and density resolution and Excellent signal to noise ratio (SNR)

Integrated Fujifilm's advanced technologies used in the image reader, software and IP offer superb quality images

High resolution reading at a 25 μm pitch, unique image processing and highly capable IP ― fusion of the best of Fujifilm's technologies realizes images of the finest quality possible expected in digital imaging.

* Researched by Fujifilm in November 2012

Unique image processing and wide dynamic range bringing high accuracy to every inspection

Automatic optimization of image quality according to the object and free presetting of parameters available

Since the introduction of the world's first digital diagnostic X-ray imaging system FCR in 1983, Fujifilm has developed imaging processing technologies suitable for objects which have undergone NDT. For DynamIx VU, we have adopted Exposure Data Recognizer (EDR) to automatically adjust the density and our proprietary image processing technology Fuji Image Processing (FIP). With these technologies, it is possible to provide optimized images of any test object. Moreover, users can customize parameter presets for image processing. Anyone can easily perform image adjustment suitable for the test object.

Integrated Fujifilm's advanced technologies used in the image reader, software and IP offer superb quality images

High resolution reading at a 25 μm pitch, unique image processing and highly capable IP ― fusion of the best of Fujifilm's technologies realizes images of the finest quality possible expected in digital imaging.

* Researched by Fujifilm in November 2012

Unique image processing and wide dynamic range bringing high accuracy to every inspection

Automatic optimization of image quality according to the object and free presetting of parameters available

Since the introduction of the world's first digital diagnostic X-ray imaging system FCR in 1983, Fujifilm has developed imaging processing technologies suitable for objects which have undergone NDT. For DynamIx VU, we have adopted Exposure Data Recognizer (EDR) to automatically adjust the density and our proprietary image processing technology Fuji Image Processing (FIP). With these technologies, it is possible to provide optimized images of any test object. Moreover, users can customize parameter presets for image processing. Anyone can easily perform image adjustment suitable for the test object.

|

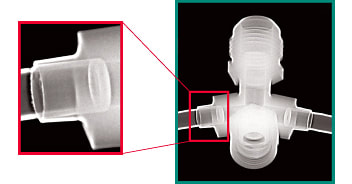

The wide dynamic range, ensuring clear depiction of an object of varying thickness

DynamIx inherits the FCR technology of Fujifilm which has been on the frontier of film and digital image resolution technologies. With the wide dynamic range of four or more orders of magnitude, every part of an object—either thick part or thin part—is clearly expressed, free from blown out highlights, blocked up shadows or unevenness. |

New Features

DynamIx VU Thickness* measurement — the automatic measurement tool makes corrosion tests easier

Focusing on the region of interest and automatically measuring the pipe wall thickness, DynamIx VU Thickness realizes more efficient and stable inspection

Different from conventional measurement based on the human eye, Fujifilm's precise image analysis technology automatically detects the inner and outer edges of pipe wall and measures the wall thickness.** Easy but accurate corrosion tests are performed reducing the need for difficult manual measurements.

Focusing on the region of interest and automatically measuring the pipe wall thickness, DynamIx VU Thickness realizes more efficient and stable inspection

Different from conventional measurement based on the human eye, Fujifilm's precise image analysis technology automatically detects the inner and outer edges of pipe wall and measures the wall thickness.** Easy but accurate corrosion tests are performed reducing the need for difficult manual measurements.

* Available as an option.

** The measurement method conforms to HOIS (09) RP1.

** The measurement method conforms to HOIS (09) RP1.

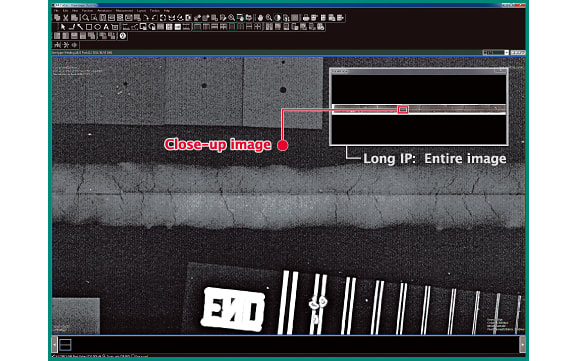

Long IPs enabling efficient exposure of welded pipe joints

|

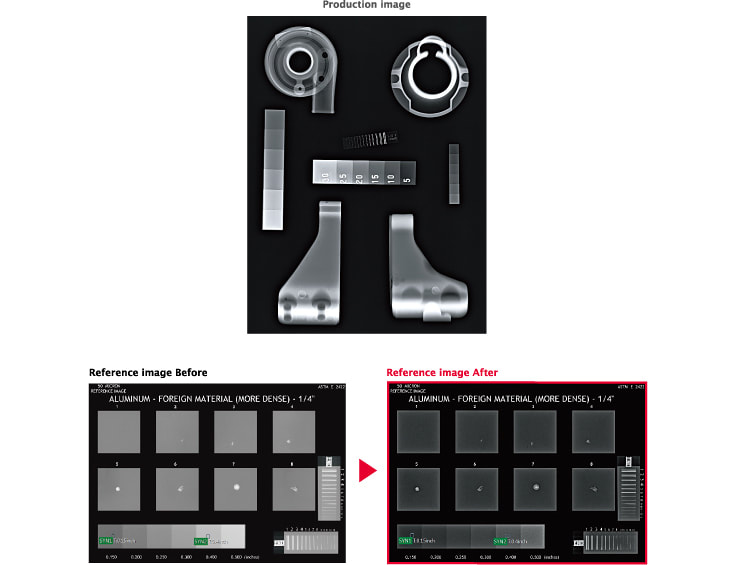

Computerized contrast normalization according to the ASTM* standard

Easily standardize inspection using ASTM digital reference radiographs and DynamIx VU software DynamIx VU Contrast Normalization** automatically adjusts the contrast of the reference image*** specified by ASTM to conform to the one of the target image. |

* American Society for Testing and Materials International, a standardization organization.

** Available as an option.

*** Steel, aluminum and titanium, as of August 2012

** Available as an option.

*** Steel, aluminum and titanium, as of August 2012

Efficient Operation

|

One click between modes

Reading and inspection possible on one computer The software enables reading and inspection to be conducted on a computer, with quick switching between the screens. Access to the image database is also smooth, so that an image appears on the inspection screen instantly after it is read. This feature enhances the work efficiency in each process. |

|

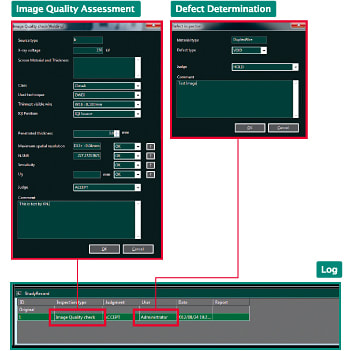

More reliable assessment and greater traceability

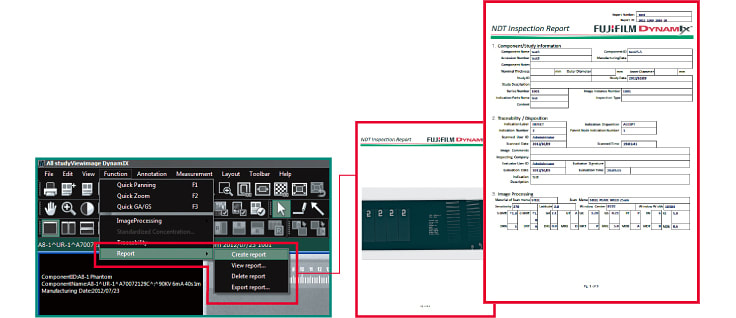

Minimized human labor for image quality assessment. Easy input of defect determination results on the special screen DynamIx VU newly offers DynamIx VU Judge* the automatic image quality assessment. This program calculates the image quality index based on the measured normalized signal-to-noise ratio (NSNR) of an image, and assesses if the index conforms to a standard image quality assessment index. This saves the need of measurement and calculation by humans. In addition to ISO standards, industry-specific standards are supported as the assessment criteria. The screen to input defect determination results is offered. The results can be recorded on the system. Automatic recording of all assessments for greater reliability Each assessment is recorded according to who, when and what, contributing to the enhanced traceability. Specified-format report creation with a little data input

With DynamIx VU Report*, reports in the specified formats are prepared automatically at the end of an NDT only by inputting test data such as the exposure conditions, results of image quality assessment and of defect determination on the relevant screens. As a report is created in Microsoft® Word®, it is readily used on other Microsoft® software. The report format or the file format is customizable. * Available as an option. |

User Friendliness

Network & Security

|

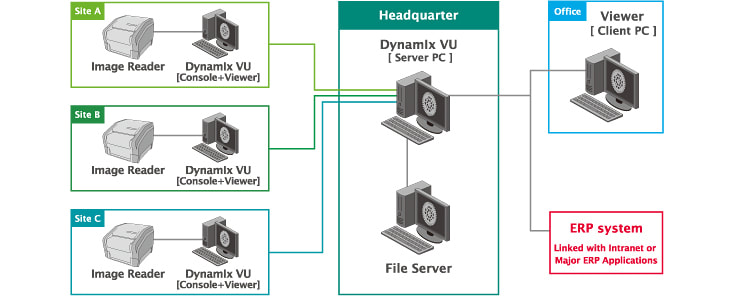

Flexible network configuration and communication to create an optimum workflow environment

Flexible network configuration and link with other systems to build the optimum workflow in a user environment The DynamIx system is customizable according to the existing network environment. By managing the inspection image data at multiple sites on a central server, an inspector can access the data anywhere via the network to assess the image. Linked with Intranet or Major ERP Applications, it is possible to send a test request made on an ERP package to each test site, or receive a test report vice versa. Thus, an efficient workflow improving the NDT process is established. Strengthened security with user authority control

Controlled user access to functions by the administrator A user's access right to each function can be assigned by the administrator to limit viewing or editing of data to the minimum necessary and strengthen the security. With this function enabled, the system shows only the functions pertinent to the user, offering simple and easy-to-use screen interface. |

Specifications

Software

DynamIx VU Console

Acquires images from the image reader and adjusts image quality.

DynamIx VU Viewer

Enables assessment of image quality and determination of defects by using various measurement tools.

DynamIx VU Server

Stores data and enables data management.

Acquires images from the image reader and adjusts image quality.

DynamIx VU Viewer

Enables assessment of image quality and determination of defects by using various measurement tools.

DynamIx VU Server

Stores data and enables data management.

Client PC

CPU

Intel® Core™ i7 CPU at 2.6 GHz or greater

OS

Windows® 7 Professional 64 bit Service Pack 1 English

Intel® Core™ i7 CPU at 2.6 GHz or greater

OS

Windows® 7 Professional 64 bit Service Pack 1 English

Server PC

CPU

Intel® Xeon® E3-1225 at 3.10 GHz or greater

OS

Windows® Server 2008 R2 Service Pack 1 English

Intel® Xeon® E3-1225 at 3.10 GHz or greater

OS

Windows® Server 2008 R2 Service Pack 1 English

Display

Standard viewer

21.2 inch 3M high resolution color LCD monitor

Recommended model

EIZO® Radiforce RX340

Resolution

1536 × 2048 pixels

High grade viewer

21.3 inch 5M high resolution monochrome LCD monitor

Recommended model

EIZO® Radiforce GX530

Resolution

2048 × 2560 pixels

21.2 inch 3M high resolution color LCD monitor

Recommended model

EIZO® Radiforce RX340

Resolution

1536 × 2048 pixels

High grade viewer

21.3 inch 5M high resolution monochrome LCD monitor

Recommended model

EIZO® Radiforce GX530

Resolution

2048 × 2560 pixels