Phoenix Microme|x and Namome|xThe Phoenix Microme|x Neo and Nanome|x Neo provide high-resolution 2D X-ray technology, PlanarCT and 3D computed tomography( CT) scanning in one system, enabling non-destructive testing (NDT) of electronic components - such as semiconductors, PCBs, lithium-ion batteries - in industrial, automotive, aviation and consumer electronics industries. With innovative engineering coupled with ultra-high positioning accuracy, Phoenix Microme|x Neo and Nanome|x Neo are ideally suited for industrial X-ray electronics inspections in process and quality control for greater productivity, failure analysis for the increased safety and quality of your products, and R&D where innovations are born.

|

BRILLIANT DXR-HD Live Imaging

|

Waygate Technologies´ exclusive brilliant DXR-HD detector fleet includes:

1) The newest large-size DXR S100 Pro detector - superior pixel resolution defining industry-leading imaging technology:

2) Exclusive high dynamic DXR250RT detector - enhanced scintillator technology introduces a new industry standard for efficient live inspection:

|

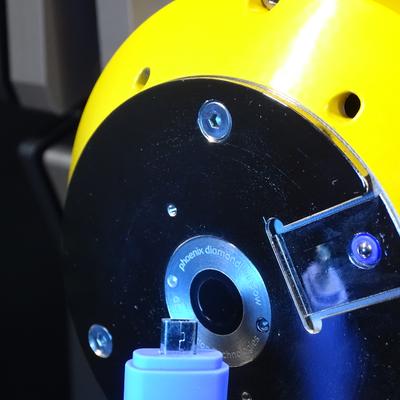

High output with high-resolution: DiamonD|Window

|

Compared to conventional beryllium targets, the Diamond|window allows higher power at a smaller focal spot. This ensures high-resolution

even at high output.

|

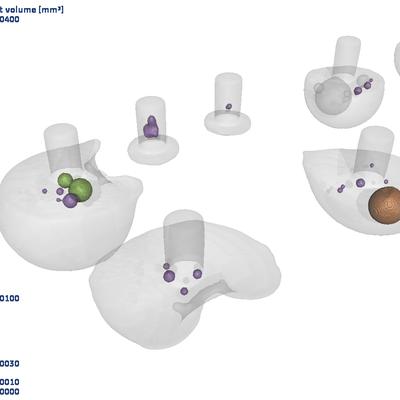

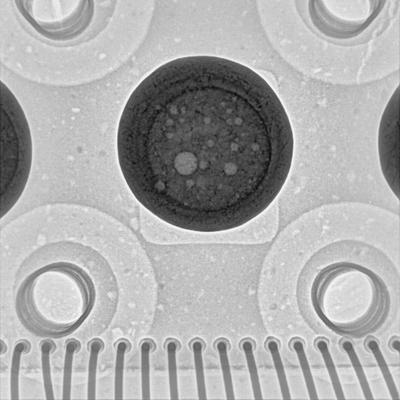

High-resolution 3D computed Tomography

|

For advanced inspection and 3D analysis of smaller samples, Phoenix|x-ray’s proprietary 3D CT technology is optionally available.

|

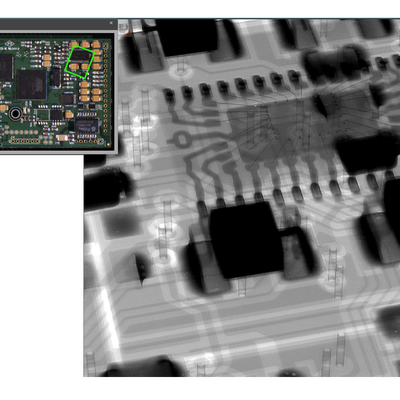

X|act - CAD based inspection: FLASH!

|

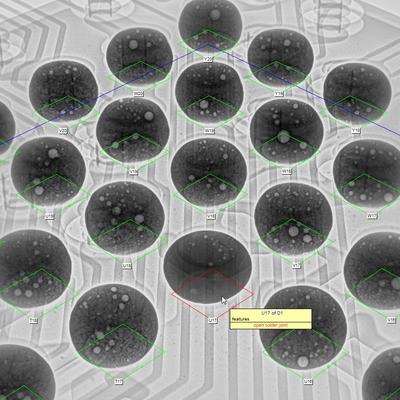

High-resolution μAXI for extremely high defect coverage

As a solution for μAXI with extremely high defect coverage, phoenix|x-ray provides its high precision systems MicromeIx Neo and NanomeIx Neo including the unique X|act software package for fast and easy offline CAD programming. Its intuitive new GUI with improved outstanding precision and repeatability, small views with resolutions of only a few micrometers, 360° rotation, and oblique viewing up to 70° ensures meeting the highest quality standards – even for inspection of components with a pitch of just 100 microns. Besides automated inspection, X|act ensures an easy pad identification by its live CAD data overlay function even in manual inspection while FLASH!™ image optimization ensures high defect coverage. |

Efficient CAD Programming

|

X|act provides not only a minimal setup time compared to conventional view based AXI – once programmed, the inspection program is portable to all X|act compatible systems. The result is fast and easy programming: just assign the inspection strategies and let X|act generate the automated inspection program

|

Virtual Board Slicing with Planar|CT

|

Planar|CT slice or multislice views allow exact inspection results of a single plane or a whole package.

|

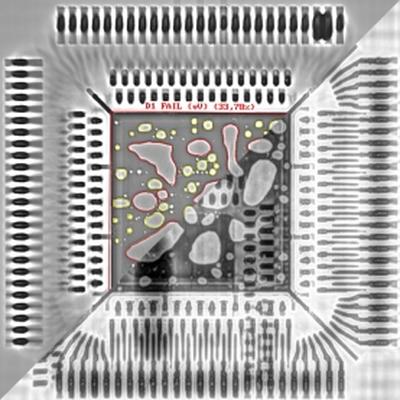

Cutting-Edge Detail Detectability, Speed, and Image Quality

|

Navigation Map Orientation

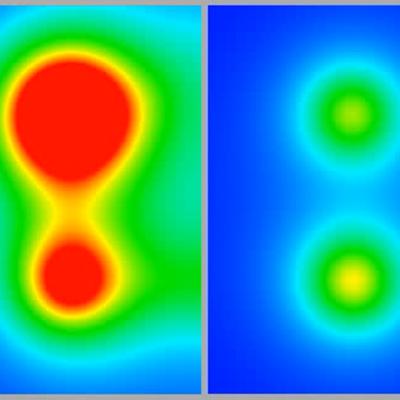

Smart Dose Management

|

Waygate Technologies´ proprietary Shadow|target inside the X-ray tube enables a reduction of unnecessary radiation dose of up to 60% compared to conventional x-ray tubes during a typical inspection. Combined in a low-dose bundle together with the brand new Dose|manager tool, it enables real-time dose monitoring and controlling

This solution protects radiation sensitive inspected components from aging to worst case damage.

Left image: Dose Map without Shadow|target. Right image: Dose Map with Shadow|target. |

Efficient and Transportable for In-Field Applications

- Minimized setup time due to highly efficient automated CAD programming

- Designed for portability with compact, state-of-the-art electronics

- Intuitive GUI interface with fully automated inspection program generation

Options for Optimization and 3D Scanning

- Optional FLASH!™ image optimization technology

- Optional advanced failure analysis with high-resolution 3D micro- or nanoCT® or large board PlanarCT

- Optional 3D CT scans up to 10 seconds