Phoenix V | tome | x M300Improving profit, safety, and throughput via 3D CT Scanning

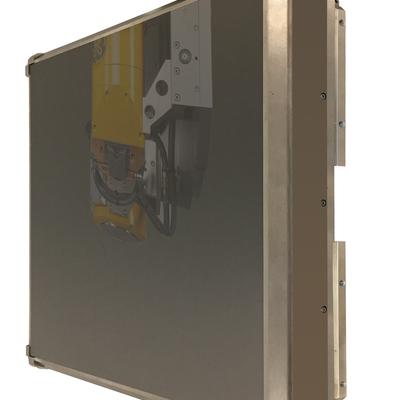

Our powerful industrial computer tomography (CT) system, designed for 3D metrology and analysis, provides industry-leading magnification at 300 kV. It is the world’s first microCT scanner with Scatter|correct technology, to automatically remove scatter artifacts for higher image quality. With a variety of proprietary premium CT technologies, the Phoenix V|tome|x M revolutionizes 3D CT metrology -- delivering faster scans and higher throughputs without compromising image quality. CT Scanning & Metrology at Higher Accuracy, Higher Speeds

|

Industry-Leading Detector Performance

|

The Phoenix V|tome|x M comes standard with our exclusive 4 MP Dynamic 41|200 next-generation photodiode design industrial X-ray detector. It provides 10x increased sensitivity relative to the state of the art 200µm pixel-size DXR detectors producing a 2-3x cycle time increase without image quality impact, making inspections and measurements more efficient and productive.

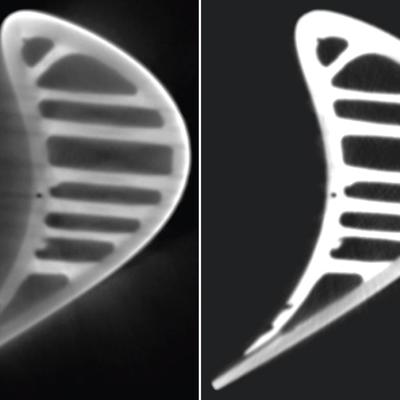

As a premium option, the 100µm / 16 MP Dynamic 41|100 detector provides 2x the resolution increase without impacting cycle times. Detection of 2x smaller defects without an increase of geometric magnification allows for the imaging of large objects at higher resolutions. Dynamic 41 digital detector technology means you get up to 2-3x faster CT scans or doubled resolution. |

Faster Scans with Less Artifacts

Unprecedented Scan Speed

Automated CT Process

Enhanced Reliability with Real Results

Backed by our proprietary technology and durable hardware, you can maintain safe and reliable operations while remaining in compliance.

Optimized inpsection Performance

By bringing your CT inspection right onto the factory floor or into the lab, you can unite manufacturing with quality control for greater reliability, speed, and efficiency.

Maximum Flexibility

Precision Metrology

AI-Based Automated Defect Recognition (ADR)

|

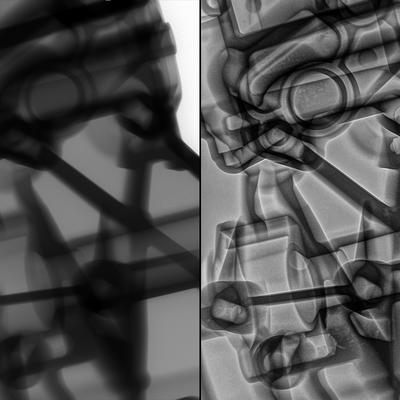

Proprietary Artificial Intelligence (AI) based algorithms deliver exceptional Automated Defect Recognition (ADR) across various flaws for e.g. battery anode overhang analysis or typical casting defects. Our AI-based ADR library yields greater accuracy and enhanced ease of use compared to conventional ADR approaches, eliminating the need for expert parameterization skills.

Waygate Technologies offers the X|approver, the next level and premium ADR platform consisting of the full and intuitive workflow management as well as a comprehensive ADR library running in the background of your production delivering automatic decision making. On top of it reporting functions are provided to see potential negative trends in production at a glance. Any authorized operator can parametrize scanned samples (e.g. for highly accurate overhang issue detection), and the algorithms get more accurate over time. |

Flash! Optimized 2D Failure Detection

|

Especially when being equipped with its optional tilt axis, the Phoenix V|tome|x M can also be used as a flexible 2D X-ray inspection system to detect failures even without performing a CT scan. The system includes Waygate Technologies X|act inspection software with industry leading Flash!™ intelligent image processing technology. Users benefit from two versions:

|