Phoenix Speed | scan CT 64High-Speed helix CT Scanner

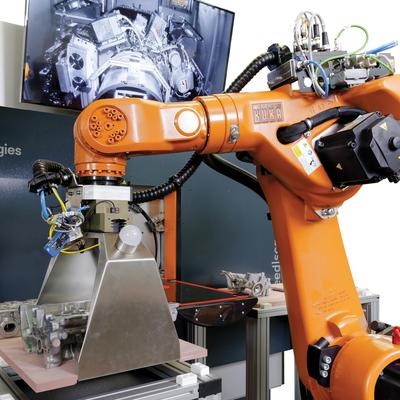

Automotive manufacturers must consistently produce high-quality parts and products while operating at maximum productivity. High resolution, high speed, full 3D inspection via in-line automation is required to ensure both safety and profitability. This goal is now attainable thanks to the Phoenix Speed|scan CT 64, a gantry-based, inline industrial CT scanner. Built on innovative Waygate Technologies, formerly GE Inspection Technologies, gantry-based CT technology proven for over four decades, our Speed|scan CT 64 provides revolutionary high-speed industrial process and production control. Combining unprecedented speed with high-quality inspection, Speed|scan CT 64 is 4x faster than initial generations and several hundred times faster than conventional industrial fan-beam CT systems. Optionally equipped with a robot, the Speed|scan CT 64 system offers unique process optimization and quality assurance possibilities for up to 100% fully automated inline CT scanning. Ensuring safety and protecting manufacturing profits with revolutionary quality inspection:

|

General Specifications

|

GANTRY-BASED INDUSTRIAL CT TECHNOLOGY

|

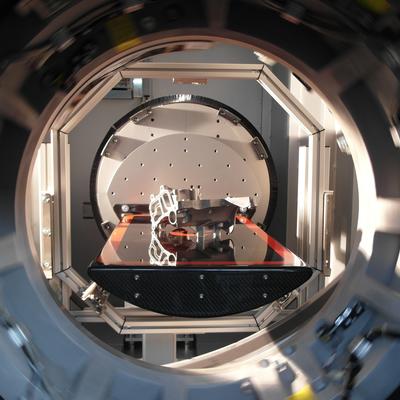

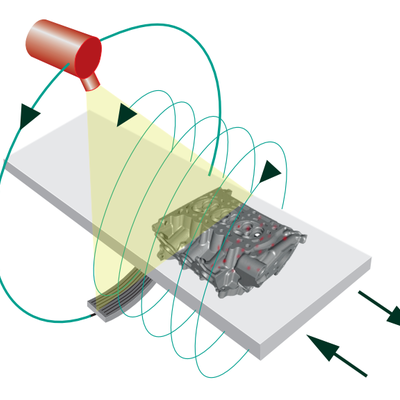

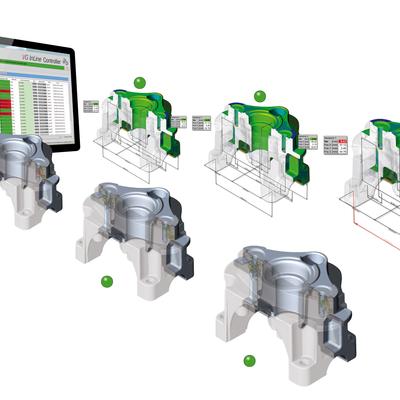

With our industrial Phoenix Speed|scan CT64 system, proven medical gantry based CT technology is available for revolutionary high-speed at-line or inline process control in the industry. The sample is being transported through the tomograph and even cylinder heads can be scanned in as little as 15 seconds.

This is about 4x faster than the first Speed|scan generation and several hundred times faster than conventional industrial fan-beam CT systems. While the next part is being loaded, the reconstructed CT data is automatically evaluated. By fast scanning of dozens of parts, quantitative production-quality data is now available, allowing immediate adjustment of the production process parameters, which have in the past been out of reach of conventional industrial fan-beam CT systems. |

advanced helix ct

|

Since CT of large castings with conventional industrial fan beam CT typically takes hours, this approach is not suitable for inspections that take place parallel to the production cycle time.

With helix multi-line technology, the workpieces are continuously scanned and automatically inspected with our own 3D Speed|ADR evaluation algorithms. To ensure the desired image quality with short measuring times and low scattering artifacts, the speed|scan CT 64 is equipped with a high-performance X-ray tube and a highly sensitive multiline detector acquiring up to 64 detector rows of scanning data during every gantry rotation. |

3D evaluation parallel to the scanning process

|

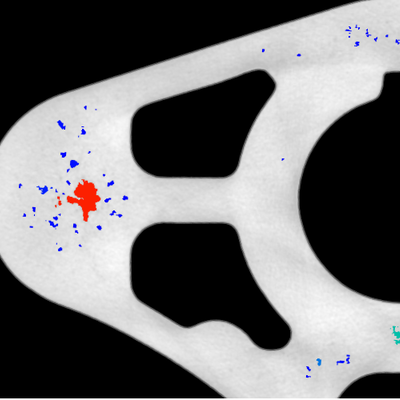

Three-dimensional analysis and process monitoring using volumetric data offer several advantages compared with a conventional radioscopic 2D inspection. Depending on the sample size and X-ray penetration length, an immediate response to processing parameters may directly lead to increased productivity:

|

Fully automatic non-destructive 3D testing and measuring

|

Especially for quality assurance of functional and safety-relevant automotive and aviation composite parts or aluminum castings, speed|scan makes it possible to perform a 100% 3D inspection for the first time. The 3 key game changers in industrial quality assurance with the advanced Phoenix Speed|scan CT system are:

|

3d Automated defect Recognition (3D Speed | ADR)

|

By combining the leading Volume Graphics industrial batch CT software with the powerful Speed|ADR algorithms, you can achieve highly precise quantitative 3D information for industrial mass production process control and optimization.

|